GP-POLYMERE

Manufacturing

Basel, Basel-Stadt

Exclusive offer: Used Regranulation Line for PET and PE Available from Switzerland: Sell Offer

Hot Offer

Hot OfferUnit : Number

PCK : On Request

QTY : 2

Details:

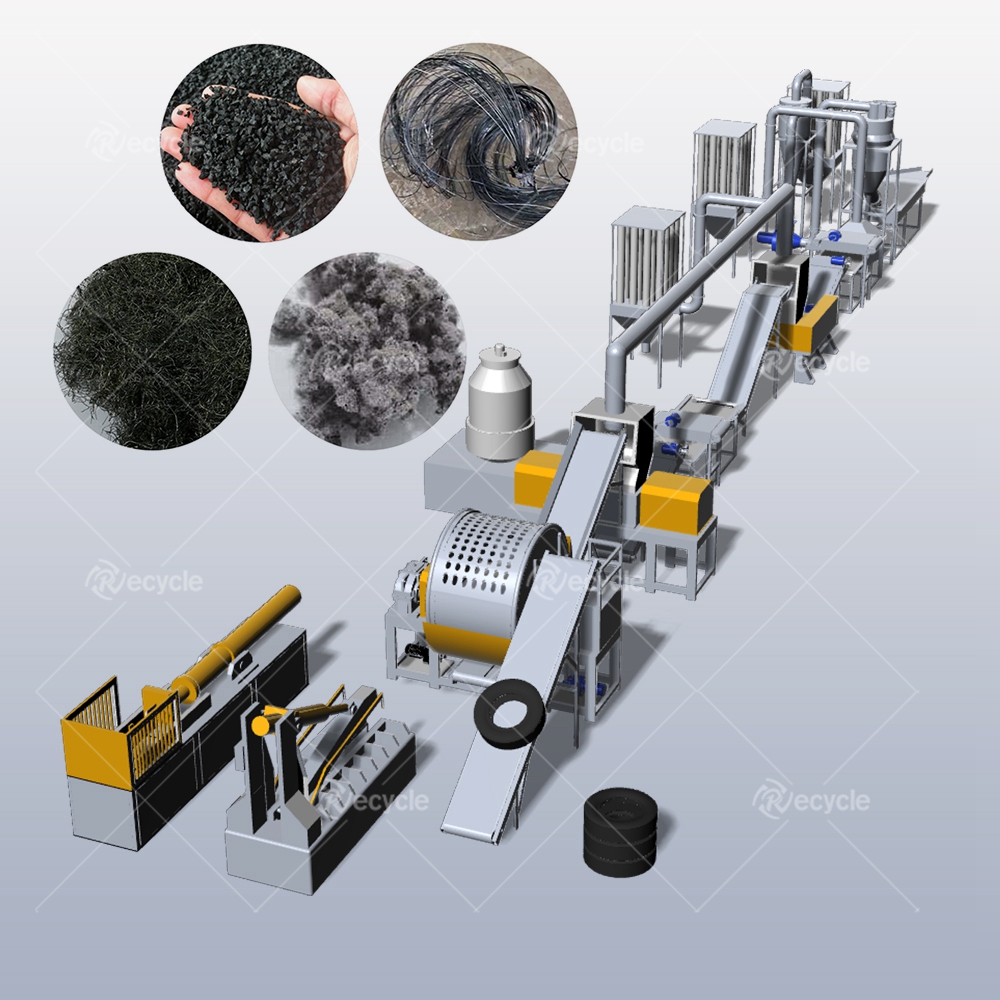

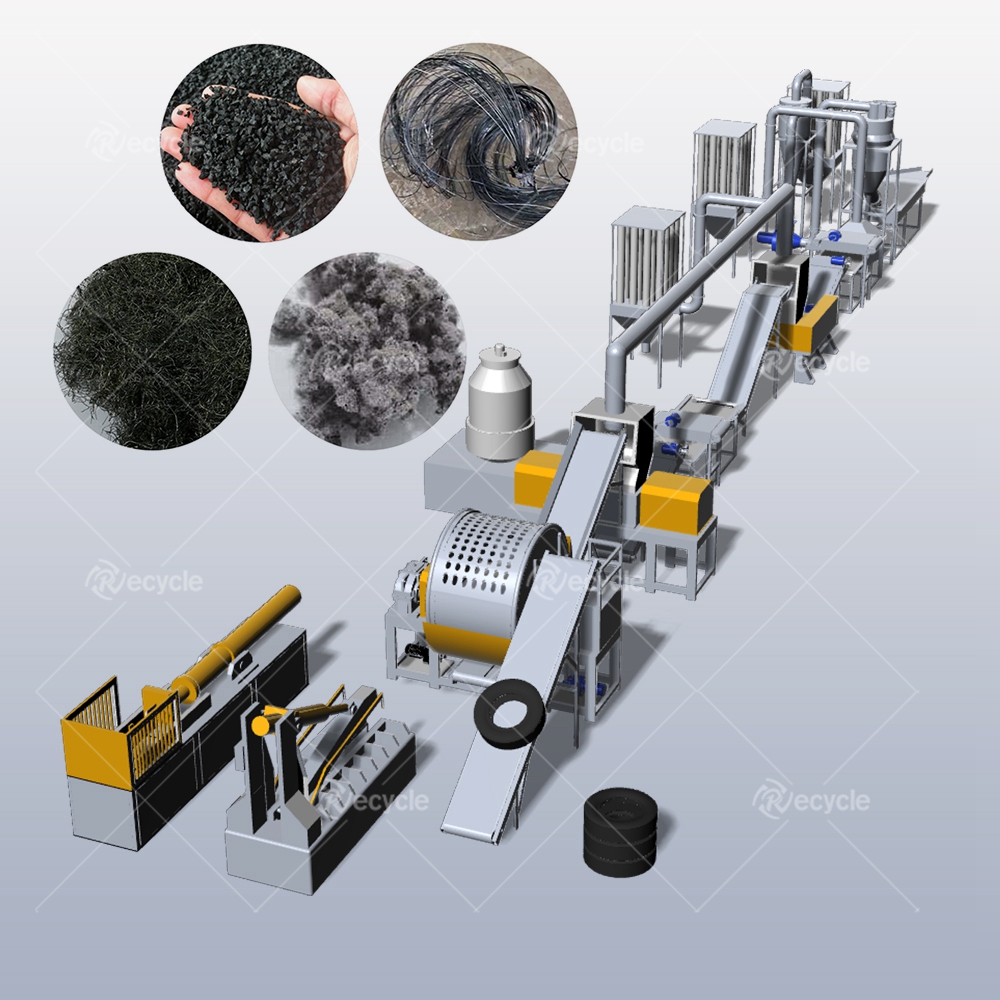

We are pleased to present a high-quality Used Regranulation Line for PET and PE, available for loading from Switzerland. This state-of-the-art regranulation line is designed specifically for the recycling of PET and PE materials. Featuring an 85 mm screw diameter, it has an impressive production capacity of 500-600 kg/h. The screw's length-to-diameter (L/D) ratio of 21 ensures efficient processing. Additionally, the machine is equipped with a degassing system that effectively eliminates unwanted gases during operation. It operates with a motor power rated at 90 kW, and the nozzle type is Spaghetti, making it suitable for processing both PET and PE materials.

The line is engineered to manage film flakes, trims, and fiber forms of material, primarily recycled PET. It is capable of producing sheets from the processed material. The BSC160 backflushing screen changer, an automatic model, provides continuous melt filtration, enhancing the output quality. This machine is ideal for recycling PET and PE sourced from post-industrial materials. It can handle dry material with a moisture content of less than 1% and is designed for clean surface treatment. The materials processed include PET thermoforming flakes and washed post-consumer material with a maximum residue of 5%, ensuring a high-quality end product.

Included in the regranulation line is a CWC110 closed water circuit for the vacuum system, which minimizes the need for fresh water for the vacuum pump. The frequency of cooling water changes is based on the contamination level of the processed material. The BSC160 backwash screen changer, manufactured in 2017, is fully automatic and pressure-controlled, allowing for uninterrupted operation and screen changes without stopping the process. We are offering this used regranulation line at a competitive price. Our company, GP-Polymere, has been a specialist in plastic scrap trading since 1999 and is located in Basel, Switzerland.

Offer Details:

Product Name: Used Regranulation Line for PET and PE

Loading Port: Switzerland

Payment Terms: T/T, LC

Shipping Terms: EXW

Preferred Region: Worldwide

For inquiries, please connect with our representative, Mr. Nilsson, who is available via email at any time to address your questions and provide additional information. We invite serious buyers to contact us for further details. Kindly share your requirements and destination port for a swift response. We look forward to your interest and are eager to assist you.

The line is engineered to manage film flakes, trims, and fiber forms of material, primarily recycled PET. It is capable of producing sheets from the processed material. The BSC160 backflushing screen changer, an automatic model, provides continuous melt filtration, enhancing the output quality. This machine is ideal for recycling PET and PE sourced from post-industrial materials. It can handle dry material with a moisture content of less than 1% and is designed for clean surface treatment. The materials processed include PET thermoforming flakes and washed post-consumer material with a maximum residue of 5%, ensuring a high-quality end product.

Included in the regranulation line is a CWC110 closed water circuit for the vacuum system, which minimizes the need for fresh water for the vacuum pump. The frequency of cooling water changes is based on the contamination level of the processed material. The BSC160 backwash screen changer, manufactured in 2017, is fully automatic and pressure-controlled, allowing for uninterrupted operation and screen changes without stopping the process. We are offering this used regranulation line at a competitive price. Our company, GP-Polymere, has been a specialist in plastic scrap trading since 1999 and is located in Basel, Switzerland.

Offer Details:

Product Name: Used Regranulation Line for PET and PE

Loading Port: Switzerland

Payment Terms: T/T, LC

Shipping Terms: EXW

Preferred Region: Worldwide

For inquiries, please connect with our representative, Mr. Nilsson, who is available via email at any time to address your questions and provide additional information. We invite serious buyers to contact us for further details. Kindly share your requirements and destination port for a swift response. We look forward to your interest and are eager to assist you.

Contact Details

Sell Offers

...moreSimilar Sell Offers

With the rising global demand for renewable energy, wind power has become an imp ...>>

Details:

Scrap Copper Chip Briquetting Press is available for sale in Shanghai. ...>>

Fiber Cutting Machine Overview:

Versatile Cutting Capability: Handles soft wa ...>>

We are prepared to provide Zinc Ores with a zinc content ranging from 35-45% Zn. ...>>

We are looking to export a steady monthly supply of Zinc Carbonate (ZnCO3), a hi ...>>

We are offering an ongoing monthly supply of 100 MT of Zinc Top Dross Galvanizin ...>>

We are offering high-quality PET cord, an essential material for tire manufactur ...>>

We are offering 100 Metric Tons (MT) of high-quality Nylon 66 scrap, specificall ...>>

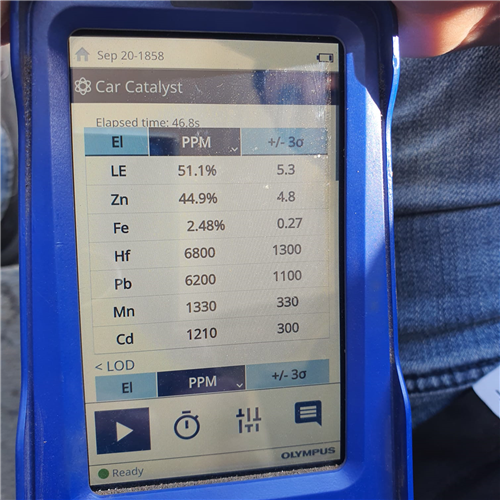

We have a stock of Zinc Ash Powder (52% Zinc Content) sourced from a steel mill. ...>>

Greensley Limited is ready to offer a consistent supply of high-quality Chrome C ...>>

We are offering 300 Metric Tons (MT) of high-quality Silica, an essential reinfo ...>>

We are sourcing 80 tons of Steel Wire on Spools, a crucial material used for tir ...>>

Can't find what you are looking for? Become a RIM member now and post your requirement

GP-POLYMERE

Manufacturing

Basel, Basel-Stadt

Exclusive offer: Used Regranulation Line for PET and PE Available from Switzerland: Sell Offer

Hot Offer

Hot OfferUnit : Number

PCK : On Request

QTY : 2

Details:

We are pleased to present a high-quality Used Regranulation Line for PET and PE, available for loading from Switzerland. This state-of-the-art regranulation line is designed specifically for the recycling of PET and PE materials. Featuring an 85 mm screw diameter, it has an impressive production capacity of 500-600 kg/h. The screw's length-to-diameter (L/D) ratio of 21 ensures efficient processing. Additionally, the machine is equipped with a degassing system that effectively eliminates unwanted gases during operation. It operates with a motor power rated at 90 kW, and the nozzle type is Spaghetti, making it suitable for processing both PET and PE materials.

The line is engineered to manage film flakes, trims, and fiber forms of material, primarily recycled PET. It is capable of producing sheets from the processed material. The BSC160 backflushing screen changer, an automatic model, provides continuous melt filtration, enhancing the output quality. This machine is ideal for recycling PET and PE sourced from post-industrial materials. It can handle dry material with a moisture content of less than 1% and is designed for clean surface treatment. The materials processed include PET thermoforming flakes and washed post-consumer material with a maximum residue of 5%, ensuring a high-quality end product.

Included in the regranulation line is a CWC110 closed water circuit for the vacuum system, which minimizes the need for fresh water for the vacuum pump. The frequency of cooling water changes is based on the contamination level of the processed material. The BSC160 backwash screen changer, manufactured in 2017, is fully automatic and pressure-controlled, allowing for uninterrupted operation and screen changes without stopping the process. We are offering this used regranulation line at a competitive price. Our company, GP-Polymere, has been a specialist in plastic scrap trading since 1999 and is located in Basel, Switzerland.

Offer Details:

Product Name: Used Regranulation Line for PET and PE

Loading Port: Switzerland

Payment Terms: T/T, LC

Shipping Terms: EXW

Preferred Region: Worldwide

For inquiries, please connect with our representative, Mr. Nilsson, who is available via email at any time to address your questions and provide additional information. We invite serious buyers to contact us for further details. Kindly share your requirements and destination port for a swift response. We look forward to your interest and are eager to assist you.

The line is engineered to manage film flakes, trims, and fiber forms of material, primarily recycled PET. It is capable of producing sheets from the processed material. The BSC160 backflushing screen changer, an automatic model, provides continuous melt filtration, enhancing the output quality. This machine is ideal for recycling PET and PE sourced from post-industrial materials. It can handle dry material with a moisture content of less than 1% and is designed for clean surface treatment. The materials processed include PET thermoforming flakes and washed post-consumer material with a maximum residue of 5%, ensuring a high-quality end product.

Included in the regranulation line is a CWC110 closed water circuit for the vacuum system, which minimizes the need for fresh water for the vacuum pump. The frequency of cooling water changes is based on the contamination level of the processed material. The BSC160 backwash screen changer, manufactured in 2017, is fully automatic and pressure-controlled, allowing for uninterrupted operation and screen changes without stopping the process. We are offering this used regranulation line at a competitive price. Our company, GP-Polymere, has been a specialist in plastic scrap trading since 1999 and is located in Basel, Switzerland.

Offer Details:

Product Name: Used Regranulation Line for PET and PE

Loading Port: Switzerland

Payment Terms: T/T, LC

Shipping Terms: EXW

Preferred Region: Worldwide

For inquiries, please connect with our representative, Mr. Nilsson, who is available via email at any time to address your questions and provide additional information. We invite serious buyers to contact us for further details. Kindly share your requirements and destination port for a swift response. We look forward to your interest and are eager to assist you.

Contact Details

Sell Offers

...moreSimilar Sell Offers

With the rising global demand for renewable energy, wind power has become an imp ...>>

Details:

Scrap Copper Chip Briquetting Press is available for sale in Shanghai. ...>>

Fiber Cutting Machine Overview:

Versatile Cutting Capability: Handles soft wa ...>>

We are prepared to provide Zinc Ores with a zinc content ranging from 35-45% Zn. ...>>

We are looking to export a steady monthly supply of Zinc Carbonate (ZnCO3), a hi ...>>

We are offering an ongoing monthly supply of 100 MT of Zinc Top Dross Galvanizin ...>>

We are offering high-quality PET cord, an essential material for tire manufactur ...>>

We are offering 100 Metric Tons (MT) of high-quality Nylon 66 scrap, specificall ...>>

We have a stock of Zinc Ash Powder (52% Zinc Content) sourced from a steel mill. ...>>

Greensley Limited is ready to offer a consistent supply of high-quality Chrome C ...>>

We are offering 300 Metric Tons (MT) of high-quality Silica, an essential reinfo ...>>

We are sourcing 80 tons of Steel Wire on Spools, a crucial material used for tir ...>>

Can't find what you are looking for? Become a RIM member now and post your requirement

Business at RIM

RIM Scrap Prices

Support & Contact

© 2003-2024 - Whitelake B2B Pvt Ltd. All Rights Reserved

- +91-8903994012

- +91-4652-230776

- 1/1/B, NH-47 road

- Suchindram, TN - 629704,

- India

Business at RIM

Support & Contact

- +91-8903994012

- +91-4652-230776

- 1/1/B, NH-47 road

- Suchindram, TN - 629704,

- India

© 2003-2024 - Whitelake B2B Pvt Ltd. All Rights Reserved