HENAN RECYCLE ENVIRONMENTAL PROTECTION EQUIPMENT CO., LTD.

Recycling Machinery Trader/Dealer/Manufacturer

Zhengzhou, Henan

Member since : 12/21/2023

Wind Turbine Blades Recycling Machine: Sell Offer

Hot Offer

Hot OfferUnit : Tons

PCK : Containers

QTY : 30 Tons

Details:

With the increasing global demand for renewable energy, wind power has become a vital component of the green energy sector. However, as wind turbines reach the end of their typical lifespan—ranging from 10 to 30 years—the need for efficient recycling and disposal of decommissioned wind turbine blades has become a pressing concern. These blades are primarily constructed from complex composite materials such as fiberglass, carbon fiber, balsa wood, foam, and resin, which pose significant challenges for conventional recycling methods. To tackle this issue, the Honest Wind Turbine Blades Recycle Machine has been developed as a crucial solution, offering an effective and sustainable approach to blade recycling.

Wind turbines consist of blades, turbines, towers, and foundations, of which the blades are the most important and difficult to handle. Glass Fiber Reinforced CompositesGlass fibers and polymer resins, typically epoxy or polyester resins. Carbon Fiber Reinforced CompositesCarbon fibers and high-performance resins, such as epoxy resin.Wood/Foam Core MaterialsThe inner core of the blade may use lightweight and lightweight materials. The inner core of the blade may use lightweight wood or foam, with composite materials on the outer layer. With a large number of old wind turbines scrapped, how to effectively recycle these blades to avoid resource waste and environmental pollution has aroused widespread concern. The concern has aroused a lot of attention. Many energy companies choose to pile up old blades next to old towers or send them to landfills, which not only takes up a lot of space but also creates a serious environmental burden. In response to this challenge, a growing number of countries, especially some in Europe and the Americas, have banned wind turbine blades from landfills and plan to implement stricter regulations by 2025.

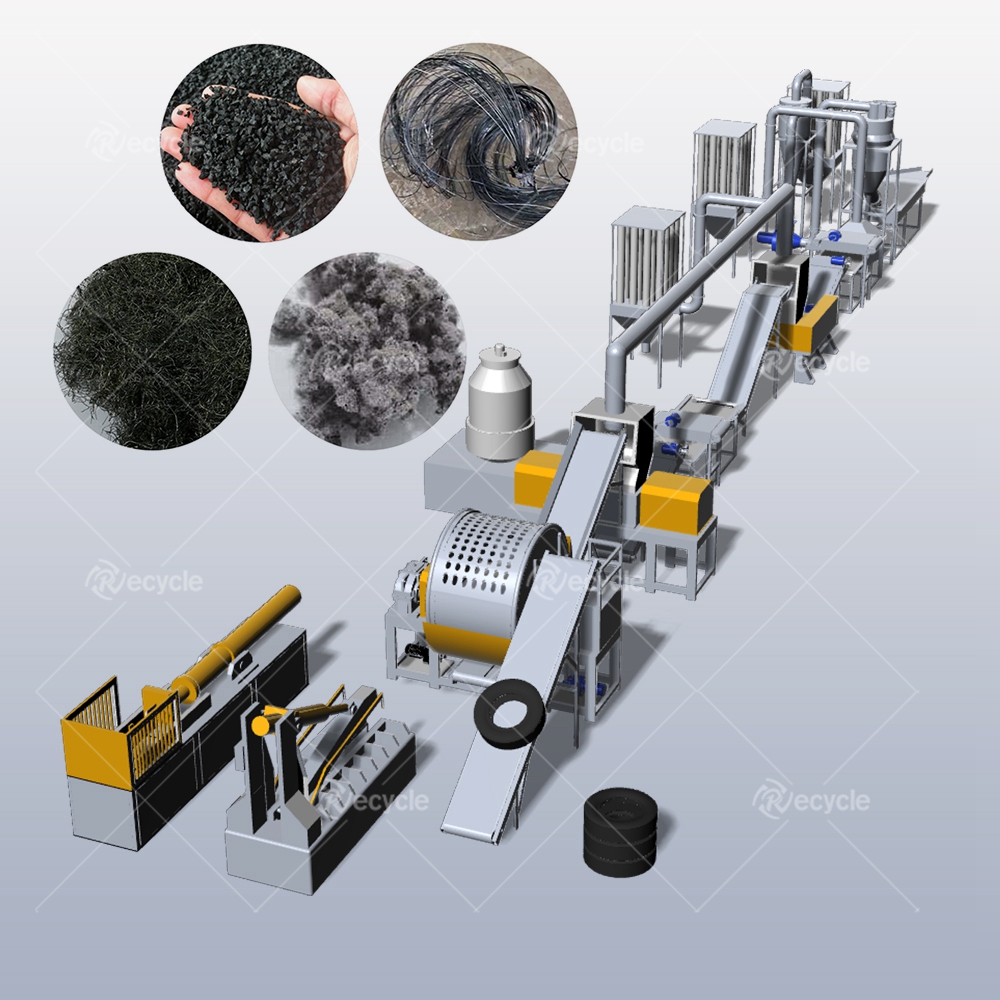

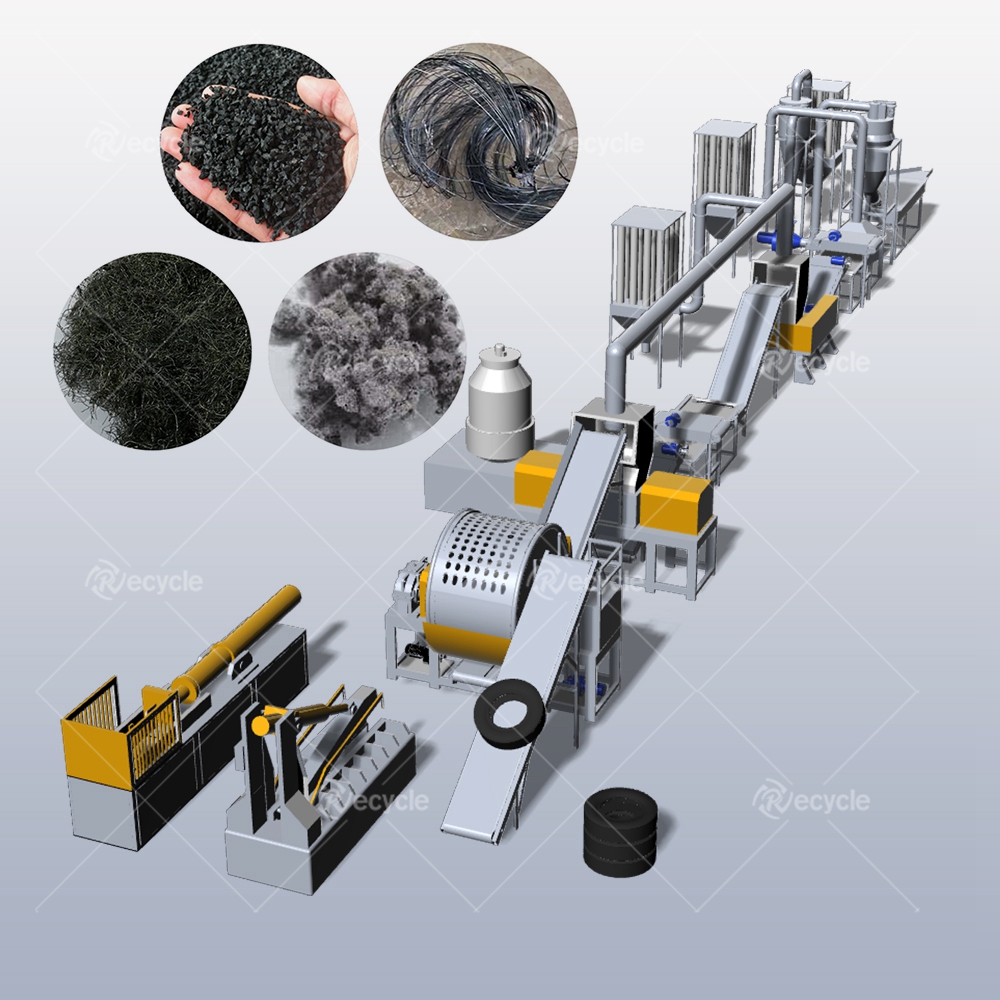

The Wind Turbine Blade Recycling Facility is a new specialized recycling facility designed to efficiently process used blades. The equipment effectively separates the glass fiber and resin materials in the blades through a series of physical treatment processes, including coarse crushing, pulverizing, wind separation, and water washing separation. In the recycling process, cut wind turbine blades enter the recycling line where the material undergoes three stages of crushing and three different separation processes. The end product consists of resin powder, small-sized fiber bundles, large-sized fiber bundles, and balsa wood. The key to the recycling process is to achieve a high purity of separation, up to 99% or more, to ensure the quality and reuse value of the recycled material.

Wind turbines consist of blades, turbines, towers, and foundations, of which the blades are the most important and difficult to handle. Glass Fiber Reinforced CompositesGlass fibers and polymer resins, typically epoxy or polyester resins. Carbon Fiber Reinforced CompositesCarbon fibers and high-performance resins, such as epoxy resin.Wood/Foam Core MaterialsThe inner core of the blade may use lightweight and lightweight materials. The inner core of the blade may use lightweight wood or foam, with composite materials on the outer layer. With a large number of old wind turbines scrapped, how to effectively recycle these blades to avoid resource waste and environmental pollution has aroused widespread concern. The concern has aroused a lot of attention. Many energy companies choose to pile up old blades next to old towers or send them to landfills, which not only takes up a lot of space but also creates a serious environmental burden. In response to this challenge, a growing number of countries, especially some in Europe and the Americas, have banned wind turbine blades from landfills and plan to implement stricter regulations by 2025.

The Wind Turbine Blade Recycling Facility is a new specialized recycling facility designed to efficiently process used blades. The equipment effectively separates the glass fiber and resin materials in the blades through a series of physical treatment processes, including coarse crushing, pulverizing, wind separation, and water washing separation. In the recycling process, cut wind turbine blades enter the recycling line where the material undergoes three stages of crushing and three different separation processes. The end product consists of resin powder, small-sized fiber bundles, large-sized fiber bundles, and balsa wood. The key to the recycling process is to achieve a high purity of separation, up to 99% or more, to ensure the quality and reuse value of the recycled material.

Contact Details

Sell Offers

...moreSimilar Sell Offers

With the increasing global demand for renewable energy, wind power has become a ...>>

Fiber Cutting Machine Overview:

Versatile Cutting Capability: Handles soft wa ...>>

We are excited to offer high-quality Mobile Washing Terminals for export. Our Mo ...>>

We are ready to offer the Rampe Container Lade Terminal. Our Rampe Container Lad ...>>

We are pleased to present a high-quality Used Regranulation Line for PET and PE, ...>>

We are pleased to introduce our high-quality Eddy Current System Machinery, avai ...>>

We are seeking buyers for high quality Lead Ingot. Our Lead Ingot has a purity l ...>>

Laminated Glass Recycling Machine separating the glass from the PVB material rec ...>>

Crinkle Paper Shredder Filler Crinkle Paper Cutter Machine with Crinkle and Stra ...>>

Rising Cores Inc is looking to export Zinc Die Cast Scrap. With a total quantity ...>>

We are offering Catalytic Converter Scrap with a total quantity of 100 MT, packe ...>>

We, Nawab Iron & Steel Re-Rolling Mills, established in 2009 and based in Kota, ...>>

Can't find what you are looking for? Become a RIM member now and post your requirement

HENAN RECYCLE ENVIRONMENTAL PROTECTION EQUIPMENT CO., LTD.

Recycling Machinery Trader/Dealer/Manufacturer

Zhengzhou, Henan

Member since: 12/21/2023

Member since: 12/21/2023Wind Turbine Blades Recycling Machine: Sell Offer

Hot Offer

Hot OfferUnit : Tons

PCK : Containers

QTY : 30 Tons

Details:

With the increasing global demand for renewable energy, wind power has become a vital component of the green energy sector. However, as wind turbines reach the end of their typical lifespan—ranging from 10 to 30 years—the need for efficient recycling and disposal of decommissioned wind turbine blades has become a pressing concern. These blades are primarily constructed from complex composite materials such as fiberglass, carbon fiber, balsa wood, foam, and resin, which pose significant challenges for conventional recycling methods. To tackle this issue, the Honest Wind Turbine Blades Recycle Machine has been developed as a crucial solution, offering an effective and sustainable approach to blade recycling.

Wind turbines consist of blades, turbines, towers, and foundations, of which the blades are the most important and difficult to handle. Glass Fiber Reinforced CompositesGlass fibers and polymer resins, typically epoxy or polyester resins. Carbon Fiber Reinforced CompositesCarbon fibers and high-performance resins, such as epoxy resin.Wood/Foam Core MaterialsThe inner core of the blade may use lightweight and lightweight materials. The inner core of the blade may use lightweight wood or foam, with composite materials on the outer layer. With a large number of old wind turbines scrapped, how to effectively recycle these blades to avoid resource waste and environmental pollution has aroused widespread concern. The concern has aroused a lot of attention. Many energy companies choose to pile up old blades next to old towers or send them to landfills, which not only takes up a lot of space but also creates a serious environmental burden. In response to this challenge, a growing number of countries, especially some in Europe and the Americas, have banned wind turbine blades from landfills and plan to implement stricter regulations by 2025.

The Wind Turbine Blade Recycling Facility is a new specialized recycling facility designed to efficiently process used blades. The equipment effectively separates the glass fiber and resin materials in the blades through a series of physical treatment processes, including coarse crushing, pulverizing, wind separation, and water washing separation. In the recycling process, cut wind turbine blades enter the recycling line where the material undergoes three stages of crushing and three different separation processes. The end product consists of resin powder, small-sized fiber bundles, large-sized fiber bundles, and balsa wood. The key to the recycling process is to achieve a high purity of separation, up to 99% or more, to ensure the quality and reuse value of the recycled material.

Wind turbines consist of blades, turbines, towers, and foundations, of which the blades are the most important and difficult to handle. Glass Fiber Reinforced CompositesGlass fibers and polymer resins, typically epoxy or polyester resins. Carbon Fiber Reinforced CompositesCarbon fibers and high-performance resins, such as epoxy resin.Wood/Foam Core MaterialsThe inner core of the blade may use lightweight and lightweight materials. The inner core of the blade may use lightweight wood or foam, with composite materials on the outer layer. With a large number of old wind turbines scrapped, how to effectively recycle these blades to avoid resource waste and environmental pollution has aroused widespread concern. The concern has aroused a lot of attention. Many energy companies choose to pile up old blades next to old towers or send them to landfills, which not only takes up a lot of space but also creates a serious environmental burden. In response to this challenge, a growing number of countries, especially some in Europe and the Americas, have banned wind turbine blades from landfills and plan to implement stricter regulations by 2025.

The Wind Turbine Blade Recycling Facility is a new specialized recycling facility designed to efficiently process used blades. The equipment effectively separates the glass fiber and resin materials in the blades through a series of physical treatment processes, including coarse crushing, pulverizing, wind separation, and water washing separation. In the recycling process, cut wind turbine blades enter the recycling line where the material undergoes three stages of crushing and three different separation processes. The end product consists of resin powder, small-sized fiber bundles, large-sized fiber bundles, and balsa wood. The key to the recycling process is to achieve a high purity of separation, up to 99% or more, to ensure the quality and reuse value of the recycled material.

Contact Details

Sell Offers

...moreSimilar Sell Offers

With the increasing global demand for renewable energy, wind power has become a ...>>

Fiber Cutting Machine Overview:

Versatile Cutting Capability: Handles soft wa ...>>

We are excited to offer high-quality Mobile Washing Terminals for export. Our Mo ...>>

We are ready to offer the Rampe Container Lade Terminal. Our Rampe Container Lad ...>>

We are pleased to present a high-quality Used Regranulation Line for PET and PE, ...>>

We are pleased to introduce our high-quality Eddy Current System Machinery, avai ...>>

We are seeking buyers for high quality Lead Ingot. Our Lead Ingot has a purity l ...>>

Laminated Glass Recycling Machine separating the glass from the PVB material rec ...>>

Crinkle Paper Shredder Filler Crinkle Paper Cutter Machine with Crinkle and Stra ...>>

Rising Cores Inc is looking to export Zinc Die Cast Scrap. With a total quantity ...>>

We are offering Catalytic Converter Scrap with a total quantity of 100 MT, packe ...>>

We, Nawab Iron & Steel Re-Rolling Mills, established in 2009 and based in Kota, ...>>

Can't find what you are looking for? Become a RIM member now and post your requirement

Business at RIM

RIM Scrap Prices

Support & Contact

© 2003-2026 - Whitelake B2B Pvt Ltd. All Rights Reserved

- +91-8903994012

- +91-4652-230776

- 1/1/B, NH-47 road

- Suchindram, TN - 629704,

- India

Business at RIM

Support & Contact

- +91-8903994012

- +91-4652-230776

- 1/1/B, NH-47 road

- Suchindram, TN - 629704,

- India

© 2003-2026 - Whitelake B2B Pvt Ltd. All Rights Reserved