HENAN RECYCLE ENVIRONMENTAL PROTECTION EQUIPMENT CO., LTD.

Recycling Machinery Trader/Dealer/Manufacturer

Zhengzhou, Henan

Member since : 12/21/2023

Household Home Appliance E waste Scrap Electric Refrigerator Washing Machine Recycling Plant : Sell Offer

Hot Offer

Hot OfferUnit : Number

PCK : On Request

QTY : On Request

Details:

Household Home Appliance E waste Scrap Electric Refrigerator Washing Machine Recycling Plant

Capacity 30-120Sets/H

WorkFlow

1. When the waste refrigerator (or freezer) is on the unpowered drum, disassemble it manually and remove the plastic and glass from the box;

2. According to different types of refrigerants, refrigerant recovery devices are used to classify and recover refrigerants. Remove the compressor and condenser, etc.

3.The whole machine enters a double-shaft shredder for shredding and preliminary crushing.

4.The materials enter the hammer crusher, and are crushed for the second time through crushing and kneading by the crusher.

5. At the same time of secondary crushing, part of polyurethane foam will be separated into foam separator by air separation. Heavy materials such as plastic and metal enter the belt conveyor.

6. Materials crushed by plastic and metal are separated by magnetic separation on the belt, and then enter eddy current separation.

7.Non-ferrous metals, such as copper and aluminum, are separated by eddy current, and plastic and foam materials are transported to the airflow separation system through belts to separate pure plastic and foam. Polyurethane foam is compressed into blocks by a foam crusher.

TEATURE

1. Negative pressure.

The whole recovery process is a sealed negative pressure environment, whichreduces the emission of gas and pollutants.

2. No pollution.

The recovery production line is equipped with a dust removal system, and thegas and particulate matter are collected and treated by the dust removal systemand discharged up to the standard.

3. Safety.

Many parts of the production line are equipped with detection facilities such astemperature and cyclopentane gas concentration, and graded alarm and safetycontrol are carred out.

4.Automation.

The refrigerator production line is equipped with an intelligent automatic controlsystem, which adopts man-machine isolation operation mode, monitors thesystem in real time through the monitoring screen, and keeps abreast of theequipment operation.

As one of the largest E-waste and Other Solid Waste Metal Recycling Machine manufacturer, our factory can provide the whole solutions. Perfect after-sales service is provided and CE certification is provided for all products.

We can dispatch engineers to overseas to help you with installation, training if you need.

Our Company has advanced technology, professional R&D team and perfect sales service system. Besides, we possess several patents and domestically-leading technologies. Our advanced equipment have been currently exported to USA, Spain, Turkey, Italy, Vietnam,Hungary, Australia, Korea, Malaysia, Singapore, India, Philippines, Ireland, Saudi Arabia, Dubai etc.

Capacity 30-120Sets/H

WorkFlow

1. When the waste refrigerator (or freezer) is on the unpowered drum, disassemble it manually and remove the plastic and glass from the box;

2. According to different types of refrigerants, refrigerant recovery devices are used to classify and recover refrigerants. Remove the compressor and condenser, etc.

3.The whole machine enters a double-shaft shredder for shredding and preliminary crushing.

4.The materials enter the hammer crusher, and are crushed for the second time through crushing and kneading by the crusher.

5. At the same time of secondary crushing, part of polyurethane foam will be separated into foam separator by air separation. Heavy materials such as plastic and metal enter the belt conveyor.

6. Materials crushed by plastic and metal are separated by magnetic separation on the belt, and then enter eddy current separation.

7.Non-ferrous metals, such as copper and aluminum, are separated by eddy current, and plastic and foam materials are transported to the airflow separation system through belts to separate pure plastic and foam. Polyurethane foam is compressed into blocks by a foam crusher.

TEATURE

1. Negative pressure.

The whole recovery process is a sealed negative pressure environment, whichreduces the emission of gas and pollutants.

2. No pollution.

The recovery production line is equipped with a dust removal system, and thegas and particulate matter are collected and treated by the dust removal systemand discharged up to the standard.

3. Safety.

Many parts of the production line are equipped with detection facilities such astemperature and cyclopentane gas concentration, and graded alarm and safetycontrol are carred out.

4.Automation.

The refrigerator production line is equipped with an intelligent automatic controlsystem, which adopts man-machine isolation operation mode, monitors thesystem in real time through the monitoring screen, and keeps abreast of theequipment operation.

As one of the largest E-waste and Other Solid Waste Metal Recycling Machine manufacturer, our factory can provide the whole solutions. Perfect after-sales service is provided and CE certification is provided for all products.

We can dispatch engineers to overseas to help you with installation, training if you need.

Our Company has advanced technology, professional R&D team and perfect sales service system. Besides, we possess several patents and domestically-leading technologies. Our advanced equipment have been currently exported to USA, Spain, Turkey, Italy, Vietnam,Hungary, Australia, Korea, Malaysia, Singapore, India, Philippines, Ireland, Saudi Arabia, Dubai etc.

Contact Details

Similar Sell Offers

We are interested in offering Electric Motor Scrap in huge quantities, available ...>>

We are looking to provide high-quality Circuit Board Scrap on a regular basis fo ...>>

We are interested in consistent supply of high-quality motor scrap. Our monthly ...>>

We specialize in the supply of 500 tons of Engine Scrap from Canada. This high-q ...>>

We are actively seeking for buyers for CPU Processor Intel 386 & 486 Scrap. This ...>>

We offer a regular supply of 100 metric tons (MT) of Ram Memory Scrap Gold Finge ...>>

Household Home Appliance E waste Scrap Electric Refrigerator Washing Machine Rec ...>>

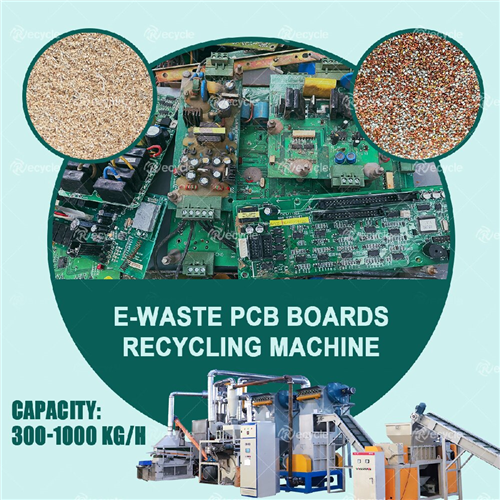

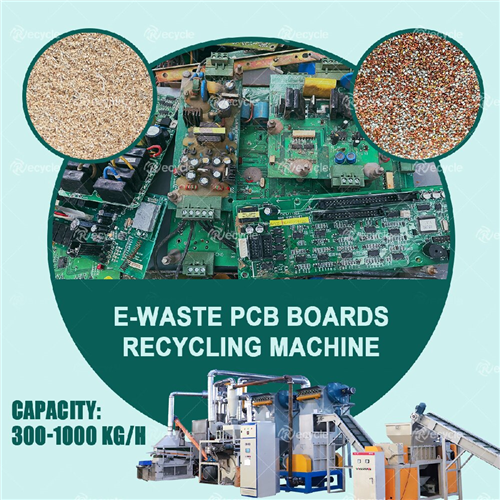

Factory Manufacturer Scrap PCB Recycling Machine E Waste Electronics Scrap Compu ...>>

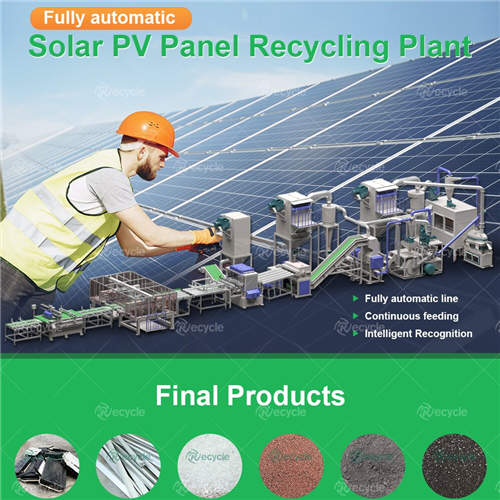

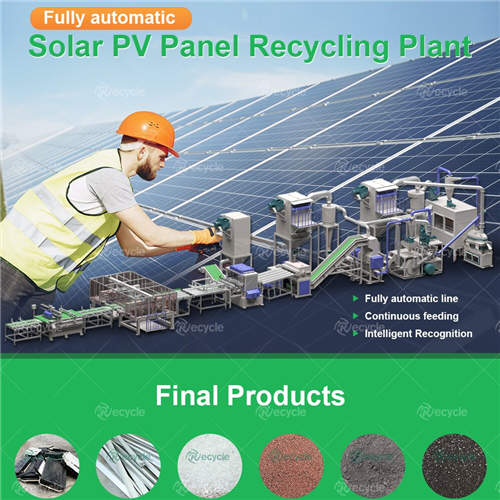

Hot Sale Machine For Recycling Pv Panels Full Automatic Photovoltaic Solar Panel ...>>

The 50kg/h---1000kg/h copper wire recycling(cable recycling machine) system can ...>>

Asim Recycling Oy is your trusted source of Non-Ferrous Metal Scrap based in Fin ...>>

We are interested in the supply of Electric Motor Scrap in a huge quantity, avai ...>>

Can't find what you are looking for? Become a RIM member now and post your requirement

HENAN RECYCLE ENVIRONMENTAL PROTECTION EQUIPMENT CO., LTD.

Recycling Machinery Trader/Dealer/Manufacturer

Zhengzhou, Henan

Member since: 12/21/2023

Member since: 12/21/2023Household Home Appliance E waste Scrap Electric Refrigerator Washing Machine Recycling Plant : Sell Offer

Hot Offer

Hot OfferUnit : Number

PCK : On Request

QTY : On Request

Details:

Household Home Appliance E waste Scrap Electric Refrigerator Washing Machine Recycling Plant

Capacity 30-120Sets/H

WorkFlow

1. When the waste refrigerator (or freezer) is on the unpowered drum, disassemble it manually and remove the plastic and glass from the box;

2. According to different types of refrigerants, refrigerant recovery devices are used to classify and recover refrigerants. Remove the compressor and condenser, etc.

3.The whole machine enters a double-shaft shredder for shredding and preliminary crushing.

4.The materials enter the hammer crusher, and are crushed for the second time through crushing and kneading by the crusher.

5. At the same time of secondary crushing, part of polyurethane foam will be separated into foam separator by air separation. Heavy materials such as plastic and metal enter the belt conveyor.

6. Materials crushed by plastic and metal are separated by magnetic separation on the belt, and then enter eddy current separation.

7.Non-ferrous metals, such as copper and aluminum, are separated by eddy current, and plastic and foam materials are transported to the airflow separation system through belts to separate pure plastic and foam. Polyurethane foam is compressed into blocks by a foam crusher.

TEATURE

1. Negative pressure.

The whole recovery process is a sealed negative pressure environment, whichreduces the emission of gas and pollutants.

2. No pollution.

The recovery production line is equipped with a dust removal system, and thegas and particulate matter are collected and treated by the dust removal systemand discharged up to the standard.

3. Safety.

Many parts of the production line are equipped with detection facilities such astemperature and cyclopentane gas concentration, and graded alarm and safetycontrol are carred out.

4.Automation.

The refrigerator production line is equipped with an intelligent automatic controlsystem, which adopts man-machine isolation operation mode, monitors thesystem in real time through the monitoring screen, and keeps abreast of theequipment operation.

As one of the largest E-waste and Other Solid Waste Metal Recycling Machine manufacturer, our factory can provide the whole solutions. Perfect after-sales service is provided and CE certification is provided for all products.

We can dispatch engineers to overseas to help you with installation, training if you need.

Our Company has advanced technology, professional R&D team and perfect sales service system. Besides, we possess several patents and domestically-leading technologies. Our advanced equipment have been currently exported to USA, Spain, Turkey, Italy, Vietnam,Hungary, Australia, Korea, Malaysia, Singapore, India, Philippines, Ireland, Saudi Arabia, Dubai etc.

Capacity 30-120Sets/H

WorkFlow

1. When the waste refrigerator (or freezer) is on the unpowered drum, disassemble it manually and remove the plastic and glass from the box;

2. According to different types of refrigerants, refrigerant recovery devices are used to classify and recover refrigerants. Remove the compressor and condenser, etc.

3.The whole machine enters a double-shaft shredder for shredding and preliminary crushing.

4.The materials enter the hammer crusher, and are crushed for the second time through crushing and kneading by the crusher.

5. At the same time of secondary crushing, part of polyurethane foam will be separated into foam separator by air separation. Heavy materials such as plastic and metal enter the belt conveyor.

6. Materials crushed by plastic and metal are separated by magnetic separation on the belt, and then enter eddy current separation.

7.Non-ferrous metals, such as copper and aluminum, are separated by eddy current, and plastic and foam materials are transported to the airflow separation system through belts to separate pure plastic and foam. Polyurethane foam is compressed into blocks by a foam crusher.

TEATURE

1. Negative pressure.

The whole recovery process is a sealed negative pressure environment, whichreduces the emission of gas and pollutants.

2. No pollution.

The recovery production line is equipped with a dust removal system, and thegas and particulate matter are collected and treated by the dust removal systemand discharged up to the standard.

3. Safety.

Many parts of the production line are equipped with detection facilities such astemperature and cyclopentane gas concentration, and graded alarm and safetycontrol are carred out.

4.Automation.

The refrigerator production line is equipped with an intelligent automatic controlsystem, which adopts man-machine isolation operation mode, monitors thesystem in real time through the monitoring screen, and keeps abreast of theequipment operation.

As one of the largest E-waste and Other Solid Waste Metal Recycling Machine manufacturer, our factory can provide the whole solutions. Perfect after-sales service is provided and CE certification is provided for all products.

We can dispatch engineers to overseas to help you with installation, training if you need.

Our Company has advanced technology, professional R&D team and perfect sales service system. Besides, we possess several patents and domestically-leading technologies. Our advanced equipment have been currently exported to USA, Spain, Turkey, Italy, Vietnam,Hungary, Australia, Korea, Malaysia, Singapore, India, Philippines, Ireland, Saudi Arabia, Dubai etc.

Contact Details

Mrs.Lisa

Similar Sell Offers

We are interested in offering Electric Motor Scrap in huge quantities, available ...>>

We are looking to provide high-quality Circuit Board Scrap on a regular basis fo ...>>

We are interested in consistent supply of high-quality motor scrap. Our monthly ...>>

We specialize in the supply of 500 tons of Engine Scrap from Canada. This high-q ...>>

We are actively seeking for buyers for CPU Processor Intel 386 & 486 Scrap. This ...>>

We offer a regular supply of 100 metric tons (MT) of Ram Memory Scrap Gold Finge ...>>

Household Home Appliance E waste Scrap Electric Refrigerator Washing Machine Rec ...>>

Factory Manufacturer Scrap PCB Recycling Machine E Waste Electronics Scrap Compu ...>>

Hot Sale Machine For Recycling Pv Panels Full Automatic Photovoltaic Solar Panel ...>>

The 50kg/h---1000kg/h copper wire recycling(cable recycling machine) system can ...>>

Asim Recycling Oy is your trusted source of Non-Ferrous Metal Scrap based in Fin ...>>

We are interested in the supply of Electric Motor Scrap in a huge quantity, avai ...>>

Can't find what you are looking for? Become a RIM member now and post your requirement

Business at RIM

RIM Scrap Prices

Support & Contact

© 2003-2024 - Whitelake B2B Pvt Ltd. All Rights Reserved

- +91-8903994012

- +91-4652-230776

- 1/1/B, NH-47 road

- Suchindram, TN - 629704,

- India

Business at RIM

Support & Contact

- +91-8903994012

- +91-4652-230776

- 1/1/B, NH-47 road

- Suchindram, TN - 629704,

- India

© 2003-2024 - Whitelake B2B Pvt Ltd. All Rights Reserved